CNC machining is getting better and better with each passing day. It is used both at commercial, non-commercial, large scale, and small scale levels. Shops like the LOCUS Precision machine shop offer many CNC machining services, ranging from prototype and small runs to refurbishing and high-precision services. The future of CNC seems very bright.

Here is what the future of CNC machining looks like in various areas:

Industry

CNC machining is a compulsory part of all major industries today. It has been made easier by the dramatic increase in digital technologies. Today it is extremely easy for anyone to manufacture any parts within less than a week.

All you need to do is to put your order online, upload your model, and leave the rest to your CNC service provider. CNC machining is equally good for start-ups, hobbyists, and personal projects. Even large companies are now taking advantage of on-demand manufacturing.

The Internet of Things (IoT)

The communication between different machines during manufacturing processes has significantly increased due to the Internet of Things (IoT). Such smart devices are capable of creating large amounts of manufacturing data with the help of machine learning techniques.

Advanced CNC Technology

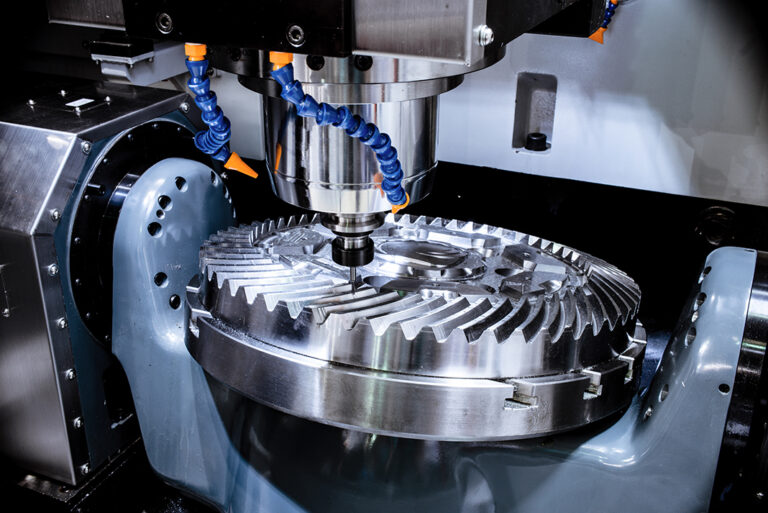

CNC machining is getting more and more advanced with the passage of time. One of the major innovations and advancements in this field is multi-axis machines.

Previously, most machines used to only work on two axes. Nowadays, five and even 7-axis CNC machines are readily available. Apart from that, CAD and CAM software have significantly improved over the years.

CNC technologies are increasingly getting more and more accessible and affordable. Programmers are trying to make more user-friendly software that will further increase the accuracy, efficiency, and precision of CNC machining.

Jobs

While CNC machining has significantly decreased manual machining, it is unreasonable to say that they are putting an end to jobs. In fact, CNC machining has created new jobs.

In the future, as CNC machines get more and more advanced and common, more jobs will be required to program, operate, and maintain them.

Conclusion

CNC machining is an advanced manufacturing process that enables the automated movements of different factory tools and machinery with the help of pre-programmed software.

CNC machining controls a lot of complex machinery, ranging from lathes and grinders to CNC routers and 3D printers. One of the most common uses of CNC machining is 3D cutting. With the help of CNC machining 3D, cutting can be easily and efficiently accomplished in just a single set of prompts.

Comments are closed.